History of Print

Modern printing began in the fifteenth century after the invention of the printing press by Johannes Gutenberg (1398-1468).

However, the history of print goes back much further in time. This blog will be in two sections. The history of print from 3000b.c. up until Gutenberg’s revolutionary invention will be part one. A brief description of the evolution of the industry up until the present day will be part two.

Part 1.

Evidence of printing techniques exists today from artefacts that are believed to date from 3000b.c. and earlier. These originate from Mesopotamia which is modern day Iraq and were created with round seals that were used to impress images onto clay tablets. Other earlier societies in China and Egypt used stamps that were then used to print on cloth. Later on the Chinese began to use wooden blocks to print onto silk.

During the Han Dynasty (around 220a.d.) a further breakthrough occurred when print was produced in the three primary colours, cyan (blue), magenta (red) and yellow. When combined with the original colour of black a kaleidoscope of virtually all other colours can be created.

During the Roman Empire, which is a little further back in the historical timeline in about 130b.c., the first ‘Acta Diurna’ appeared. This is Latin for ‘Daily Acts` and can be considered as the first ever newspaper. However, they were not printed, at the time they were carved onto stone or metal and scribes then made copies and distributed them in order to disseminate news and ideas to the provinces of the Empire. This was an important breakthrough because newspapers and print were to become synonymous for centuries until the present day.

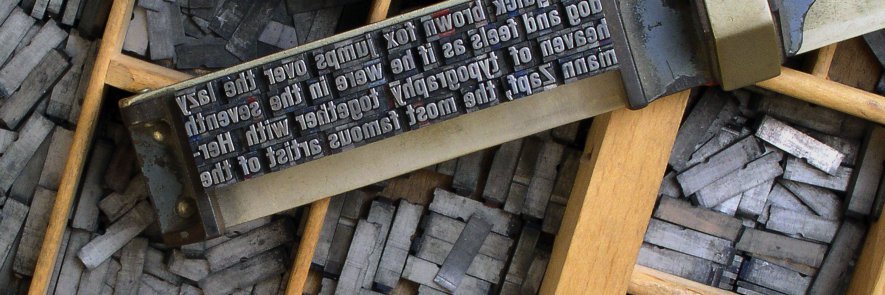

The first moveable type printing press (image above) was invented in China by an alchemist named Bi Sheng around the year 1040a.d. This was an important technological breakthrough because for the first time it became possible to mass produce a text or book incredibly quickly and efficiently compared to anything else before. There are still a few surviving books produced from the clay-baked moveable type characters in 12th century China.

However, because of the complexities of Asian writing systems (Chinese, Korean and Japanese alphabet was made up of thousands of characters which each would need to be cut individually for moveable printing) this method did not really catch on and the widespread use of wooden blocks continued in China.

It was the Europeans who really embraced moveable type and in the middle of the 15th century Johannes Gutenberg invented what can be considered the first Printing Press. What set Gutenberg apart from his Chinese predecessors was the mechanisation of the transfer from moveable type to print.

By automating the process using machine rather than hand assembly, mass production was made possible, combined with superior ink using linseed oil and soot instead of the Chinese water-based ink. Cost efficient, production printing of books began on an industrial scale and the Print Industry began on its exponential, profitable growth journey.

Although the first lithograph offset press was invented by Englishman Robert Barclay in 1875 using two cylinders, one made of hard stone or metal and the other made of rubber which was used to pull the item being printed upon through the press, the real technological breakthrough emerged a few years later by a discovery made by Ira Washington Rubel in America. It happened by accident, while operating his lithographic press, he noticed that if he failed to insert paper the metal plate would transfer the image onto the rubber impression cylinder. If paper was then placed into the machine the image would appear on both sides. To his amazement the image from the rubber impression was far superior and created a sharper, clearer look. He quickly exploited his ‘mistake` and is credited with inventing the first offset printing press as we have come to know it today.

Part 2.

If we compare the printing methods with today’s litho print machines we can understand that recent technology has led to hugely impressive production workhorses capable of quick drying times and versatile enough to print on plastic substrates as well as traditional paper and magazines. Today, speed of production and turnaround times are vital for any printing business to gain competitive advantage. High quality, waste reduction and fully loaded with the latest UV and LED technologies, print machinery manufacturers are just as competitive with each other in the pursuit of business in the form of capital investment as printers are with each other as they ruthlessly undercut each other to win consumer facing customers.

Heidelberg is arguably the market leader for providing printing presses and has achieved an unprecedented boost in sales in the U.K.recently. An example of this is speedmaster XL75 62 five-colour press, it has an impressive automatic colour and register adjustment system and the evidence available suggest that the investment is certainly worthwhile. In today’s industry the most competitive, efficient firms tend to use this incredibly reliable piece of machinery and it will be interesting to see the next breakthrough regarding quality and automation. Printing firms will continue to seek new business and improvements regarding productivity and waste reduction will be key selling points for suppliers like Heidelberg. The industry has certainly come a long way since the wooden blocks and clay tablets mentioned earlier.

on all orders

Emailed Proof

Company

up to 80% Faster